Radiant Ice Melt System Detection

See What's Really Going On!

Ice and snow melt systems are widely used across Massachusetts in various applications. Business owners implement these systems in outdoor malls, parking lots, car washes, walkways, and loading ramps to reduce the costs of ongoing snowplowing, prevent vehicle skidding, and minimize the risk of slip-and-fall accidents on their property in the winter months.

As a convenience, homeowners of high-end properties install ice and snow melt heating systems in exterior surfaces, such as driveways, sidewalks, stairs, and patios, completely eliminating the need for strenuous shoveling or snow removal.

There are two types of ice and snow melt systems in Massachusetts: embedded electric heat cables and hydronic piping. Based on my experience, the majority of ice and snow melt systems in Massachusetts are hydronic systems. These systems consist of a closed-loop tubing made from a flexible polymer (typically cross-linked polyethylene) or synthetic rubber, which circulates a mixture of hot water and propylene glycol (antifreeze), similar to the fluid used in an automobile radiator. A boiler heats the fluid to temperatures between 140 to 180°F, providing sufficient heat to melt any snow that may accumulate on exterior surfaces. The concealed ice melt tubing, ranging in diameter from 1/2 to 3/4 inch, is flexible enough to be arranged in spiral or serpentine patterns (as shown in my infrared images below) to ensure even heat distribution and effectively warm any exterior surface.

These in-slab snow melt systems are designed for long service life, but as with any material, continuous use will eventually lead to wear and tear. When these embedded systems fail, plumbing repairs become necessary. The challenge with repairing these systems is that the heating elements are completely embedded in the concrete, meaning that any repairs require the removal of the concrete surrounding the damaged section. Locating the exact point of a rupture in a large ice and snow melt system is impossible through visual inspection alone, which is where Thermal Imaging becomes invaluable for detecting the precise trouble spot.

A rupture in concealed hydronic tubing can be easily detected with a simple infrared (thermal) scan, eliminating any guesswork. I simply scan the entire snow and ice melt surface with my infrared camera, allowing me to quickly detect every embedded heat pipe once the system begins to heat up. If there are any ruptures, breaks, or leaks in the piping, they will appear as anomalies, and the affected area can be precisely marked with temporary spray paint. This area can then be carefully excavated (with minimal risk of damaging the existing piping), and the necessary repairs can be made. Once the repair is complete, the breached area can be patched up. Infrared detection ensures that your repair work is as minimal as possible.

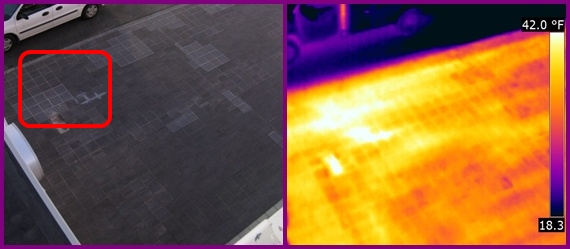

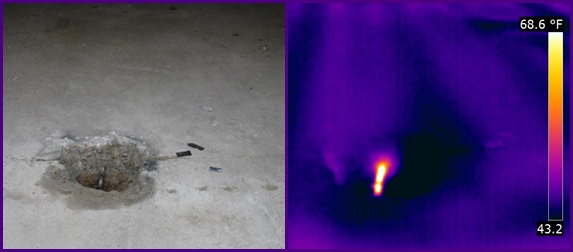

The Ernie Bach Jr. Honda dealership in Norwood, Massachusetts (re-branded as Nucar Honda) experienced a major leak in their ice and snow melt system but was unable to locate the concealed pipe leak through visual inspection.

With roof access, I was able to quickly detect and pinpoint the exact location of the buried ruptured pipe.

Infrared imaging enables me to pinpoint the exact location of a pipe burst in the radiant ice and snow melt system.

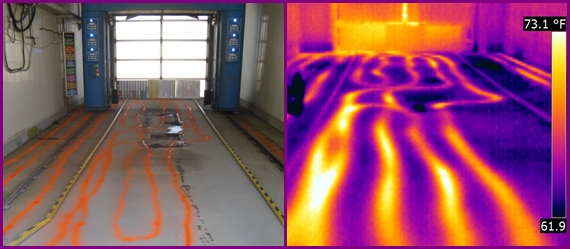

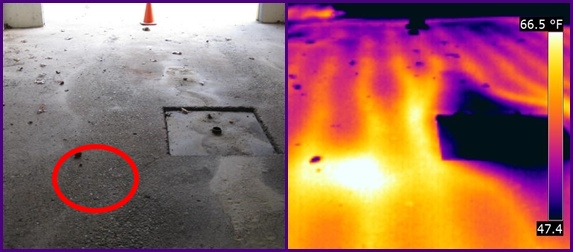

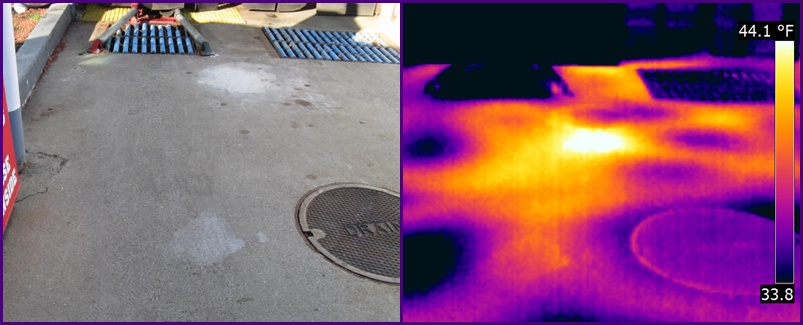

An automatic car wash, installed directly above an ice and snow melt system, had to be replaced without disturbing the concealed radiant heat piping beneath it.

My infrared scan made it possible to replace the heavy-duty car wash machinery without disturbing the heat pipes embedded in the concrete floor below.

Temporary orange marking paint was used to identify the locations of all concealed pipes. Marking these pipe locations provided a clear guideline for installing the new automatic car wash. As seen, the embedded ice melt piping is never completely straight.

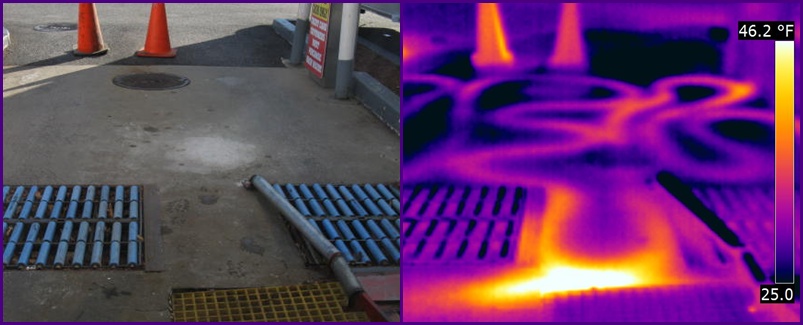

Thermal imaging allows me to quickly detect and pinpoint the exact location of the main supply line for this radiant ice and snow melt system.

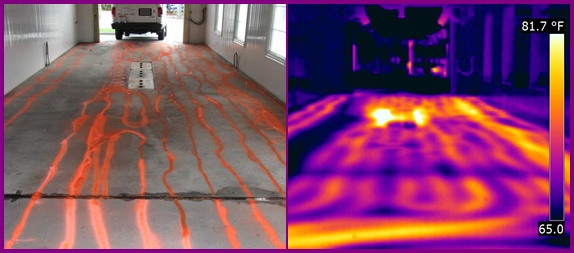

Another automatic car wash upgrade requires infrared scanning to accurately detect the location of all embedded piping. As shown, the buried pipes do not remain perfectly straight when contractors pour concrete over them. Note the two-foot void on the left.

After mapping out the embedded pipes within this car wash bay (above), the automatic car wash was securely bolted to the floor without any issues.

This is another car wash with a failed radiant ice melt system. The bright yellow area clearly shows where the embedded piping has failed.

The concrete floor was carefully breached, and a plumber successfully repaired the damaged pipe without having to tear up the entire car wash bay.

Here is another embedded pipe that has failed. The leak is easily detected by the bright yellow area in the infrared image.

After breaching the concrete floor, the active leak was immediately apparent.

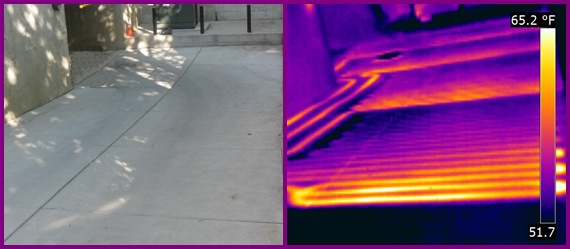

Here is another embedded radiant heat pipe that has failed on an exterior walkway. The bright yellow area in the infrared image highlights the issue.

After breaching the concrete walkway, the leaking pipe was clearly visible.

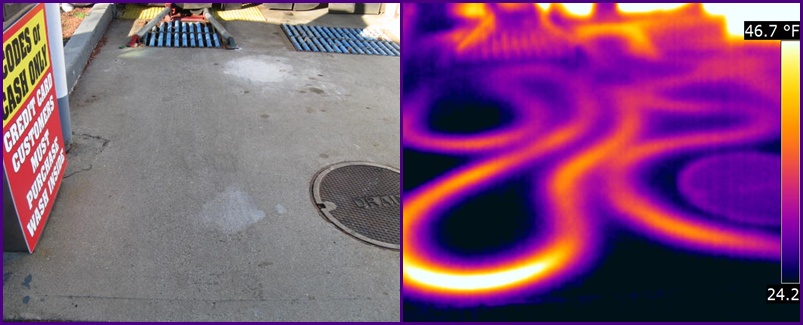

This ice melt system has been "ON for approximately one hour. I am now detecting an embedded pipe leak at the bright yellow area.

It gets worse. See next two images for details...

Looking in the opposite direction, this ice melt system appeared to be in good condition with no leaks. However, after waiting over an hour, I detected major issues. See the next image for details...

Infrared imaging reveals another bright yellow area, indicating a defective embedded pipe. This entire system needs to be repaired or replaced immediately.

For more information, please go to the top right corner and click "Navigate."