Insulation - Missing, Damaged or Wet

See What's Really Going On!

Massachusetts homeowners spend a significant amount of their hard-earned money on heating and cooling. With rising fuel and electricity costs, the best way to cut expenses is to identify and seal the areas where energy is being lost. I can help you reduce these costs using advanced infrared technology. This allows me to pinpoint exactly where your home is losing conditioned air, so you can take action to keep it inside longer. As a result, you’ll spend less on heating and cooling while improving your home's comfort and efficiency. In a typical home, heating and cooling account for over half of total energy costs. With my expertise, I’ll show you how to lower this expense—starting today.

An infrared inspection with thermal imaging is exactly what you need! This advanced technology provides an instant snapshot of active energy losses through your home’s walls and ceilings. Thermal imaging visually maps areas where insulation is damaged, settled, or improperly installed, revealing hidden inefficiencies. By detecting temperature variations, I can assess the adequacy of your home’s insulation and identify problem areas in real time. Poor insulation conducts heat instead of retaining it, making energy loss easy to spot. Any major surface temperature differences indicate areas that need insulation upgrades—helping you save money on heating and cooling while improving comfort and efficiency.

Keep in mind that minor air leaks are inevitable in exterior walls and ceilings due to wood structural members that conduct exterior air at transition points—areas that simply can't be insulated. However, I can walk you through your home and pinpoint the major problem areas where excessive air infiltration is driving up your energy bills. By identifying these critical leaks, you can take action to improve efficiency and reduce costs.

After identifying the inefficient areas in your home that need improvement, I will provide you with comprehensive professional IR report highlighting the key areas requiring an insulation upgrade. You can use this report as a detailed guide to address these problem spots yourself or share it with an insulation contractor, who can use it as a mapping tool to locate and correct insulation defects throughout your home.

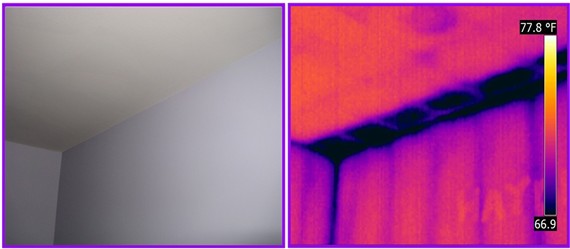

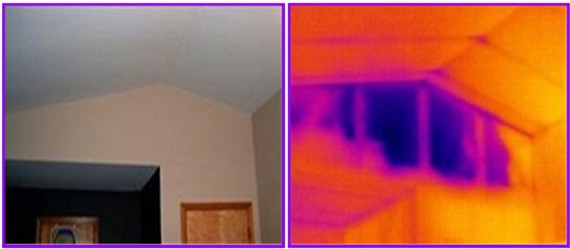

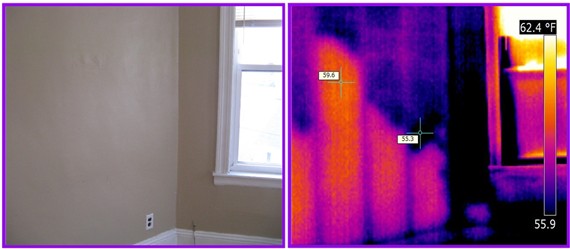

Take a look at the concealed structural cavities where infrared has revealed insulation gaps. Brighter colors indicate HEAT, while darker colors highlight COLD air leaks.

A visual inspection of this ceiling may appear flawless, but my thermal scan reveals missing insulation along the entire perimeter.

This wall appears perfectly fine—until my infrared camera reveals settled insulation.

This room may look fine at first glance, but my infrared camera exposes missing insulation at all outer ceiling cavities.

This ceiling looks fine at first glance, but my infrared camera reveals a large hidden void.

Visually, this wall looks perfectly fine, but my infrared scan reveals missing insulation behind the attic knee space—allowing cold air to seep in, much like an open window.

I was hired to inspect a recent blown-in insulation installation. While it looks great visually, the infrared scan reveals poor workmanship.

The outer ceiling cavities in this bedroom are lacking insulation.

SPRAY FOAM INSULATION

Manufacturers of this innovative product claim that spray foam insulation is energy-efficient, environmentally friendly, and that it fully expands to fill all cracks, crevices, and voids. They also assert that foam insulation creates an effective air-tight seal to prevent air infiltration, the leading cause of energy loss in buildings. While their claim that spray foam is the best insulation on the market is absolutely true, its performance depends entirely on the application. If the foam is not mixed correctly on-site or if it's not applied to the manufacturer's specifications, it will not deliver the intended results, ultimately defeating its purpose.

Based on my experience, I can confidently say that foam insulation is not perfect until the installation is verified with an infrared scan. I’ve conducted numerous infrared inspections on newly constructed homes with foam insulation, and I have only come across one flawless application. (See image at bottom of this page). Imperfections occur due to air bubbles that form as the foam expands, creating voids that allow exterior air to infiltrate your living space. An infrared scan will identify these gaps, allowing the installer to add more foam and achieve the air-tight seal necessary for an energy-efficient home.

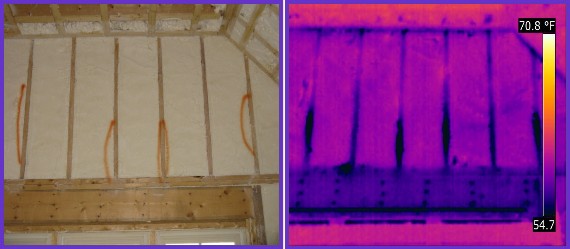

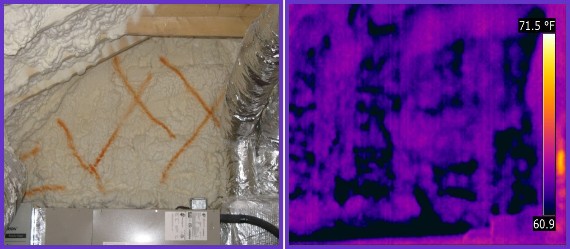

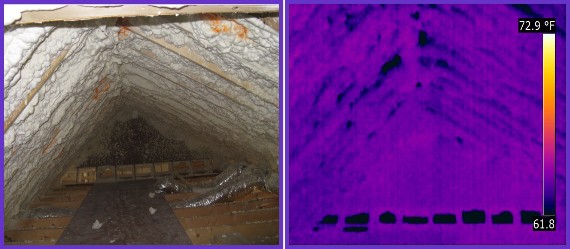

Take a look at the following images of a foam insulation application before the drywall was installed. A local building contractor hired me to verify that there were "NO voids" within the thick foam insulation applied to the ceiling and wall cavities. They wanted peace of mind before proceeding with the drywall installation. My infrared scan quickly identified minor voids, which they marked and upgraded during the thermal scan.

The foam insulation failed to create a tight seal at the lower portion of these wall studs, while the top portion appears well-insulated.

Observe the numerous voids present throughout the entire foamed-in wall.

The foam insulation in this attic cavity appears adequate, but infrared detection reveals minor inefficiencies.

This foam application is flawless—a rare achievement.

For more information, please go to the top right corner and click "Navigate."