Radiant Heat Pipe Detection

See What's Really Going On!

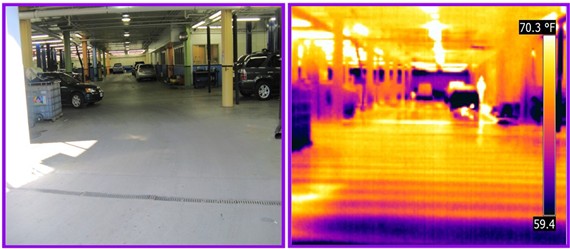

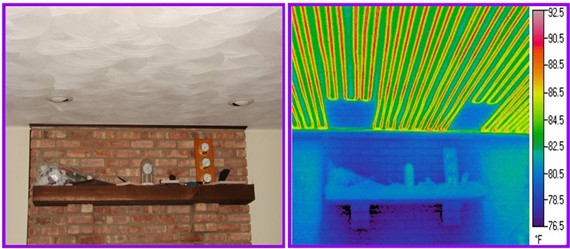

COMMERCIAL RADIANT FLOOR HEATING SYSTEM

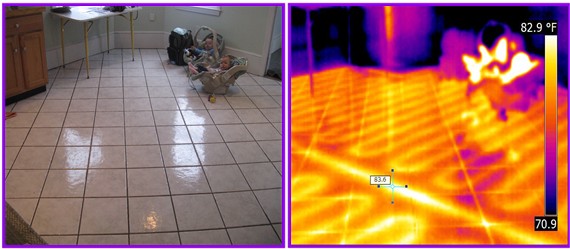

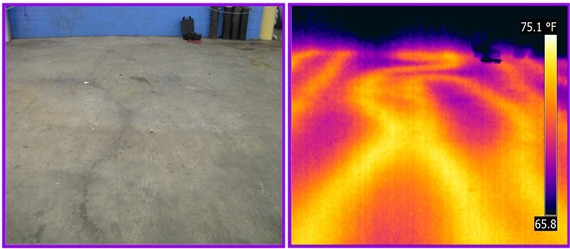

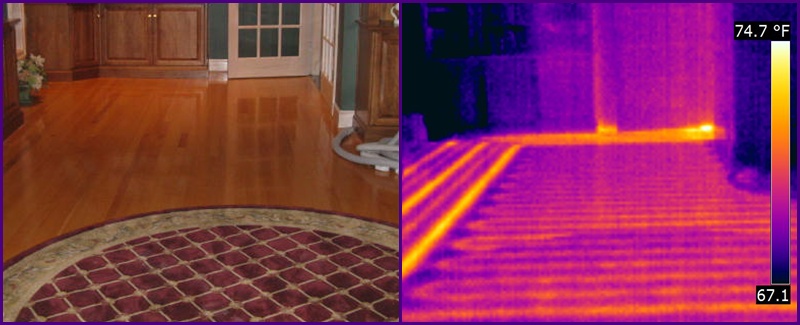

RESIDENTIAL RADIANT FLOOR HEATING SYSTEM

Radiant heating systems are commonly installed in the floors and ceilings of homes and businesses throughout Massachusetts. The continuous hot water supply pipes used in these systems are concealed, making them impossible to visually inspect or monitor on an ongoing basis to ensure proper functionality and detect leaks. Due to the hidden nature of radiant heat piping, it is essential to have the system professionally inspected and monitored annually.

Undetected leaks in a radiant heating system can lead to significant energy waste and cause substantial property damage if not promptly repaired. Locating a leaking hot water pipe beneath a concrete slab can be both time-consuming and expensive. In many cases, identifying the precise location of a leak requires removing or breaking apart large sections of flooring, resulting in further structural damage and costly repairs.

Older radiant heating systems with steel or copper pipes, particularly those over 30 years old, are especially prone to failure. These concealed leaks often go unnoticed until visible signs of moisture damage appear or until I conduct an inspection using my infrared camera, which can effectively detect temperature anomalies caused by leaking hot water. Proactive monitoring and timely maintenance are crucial to preventing extensive damage and preserving your property.

CLICK IMAGE ABOVE

Watch how infrared scanning is performed on radiant floor heat.

This radiant floor heating system appears visually intact, but infrared imaging reveals leaks in the embedded piping.

This radiant heat system appears fine visually, but infrared imaging detects a leak.

I provide a reliable and highly effective solution for locating and monitoring hidden radiant heating pipes. Using advanced infrared (thermal imaging) technology, I can detect thermal variations in buried heating pipes, accurately pinpointing their locations and identifying concealed leaks beneath various floor or ceiling materials.

My infrared camera’s exceptional sensitivity allows me to map out entire radiant heating systems, regardless of size. This state-of-the-art technology not only reveals the precise placement of supply tubing within your floor or ceiling but also measures pipe temperatures and uncovers hidden leaks that might otherwise go undetected.

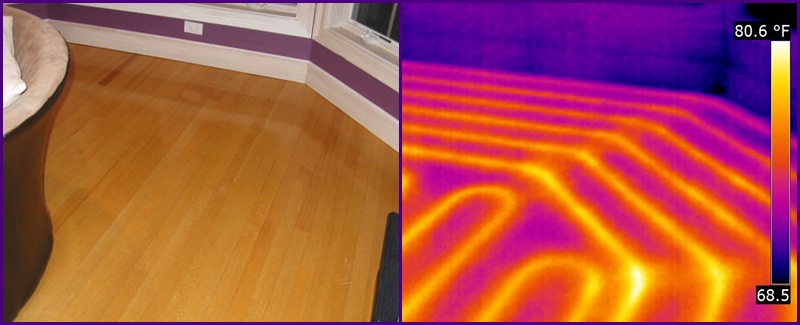

If you're planning to renovate or remodel over or near a radiant heating system, I strongly recommend having the radiant piping thoroughly inspected and accurately marked before beginning any construction work. Without knowing the exact location of these buried pipes, accidental punctures can occur, leading to costly repairs and project delays. Taking this precaution can save you time, money, and unnecessary complications.

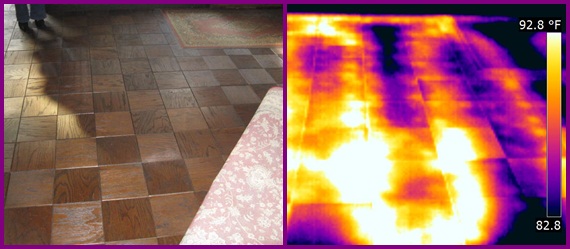

During my radiant heating inspections, I’ve encountered numerous cases where irregular patterns in the embedded radiant lines were evident, with inconsistent spacing between the pipes (see image below). This often occurs when heating pipes aren’t properly secured during the concrete pour, causing them to shift out of position and resulting in a misaligned installation.

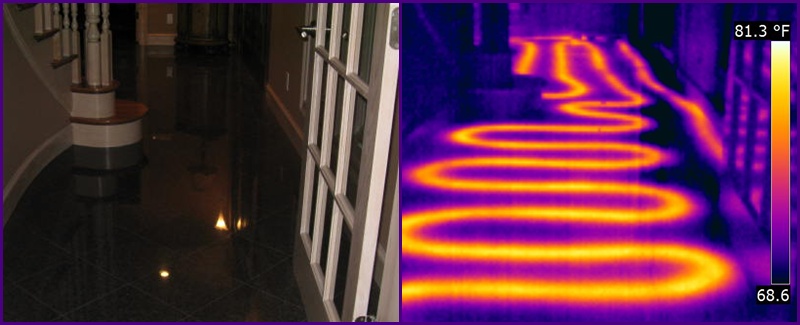

Knowing the exact layout of your radiant pipes and ensuring they are spaced evenly is invaluable. In some instances, displaced radiant heat coils may end up dangerously close to surfaces, increasing the risk of accidentally puncturing a pipe with a drill bit or other hardware during construction or renovation. Such damage can lead to significant downtime, as well as the costly and labor-intensive process of using jackhammers to break through the floor or ceiling for repairs.

A thermal scan of the radiant piping area before construction could prevent these issues entirely. By hiring a professional thermographer like myself to map out the radiant heating system, you can avoid unexpected setbacks and ensure your project proceeds smoothly.

MAPPING OUT EMBEDDED RADIANT PIPING

Notice the Irregularities in This Radiant Floor Piping Layout

Precision Was Essential for This IR Scan — A Commercial Vehicle Lift Will Be Installed Here

Radiant Pipe Locations Are Being Accurately Marked

Infrared Technology Enabled the Safe Installation of Two Commercial Vehicle Lifts Without Damaging the Embedded Heat Piping

This Radiant Heat Piping Was Installed in a Clean, Even Octagon Shape

Infrared Effortlessly Detects Radiant Piping Beneath a Marble Floor

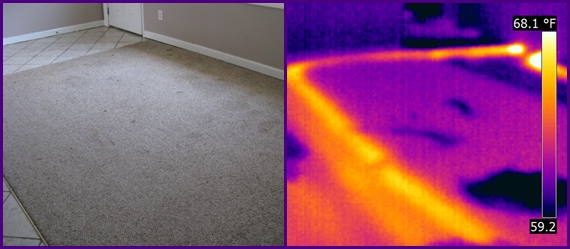

The Oval Carpet Does Not Interfere with the Detection of Radiant Piping Beneath the Floor

Infrared in Action – Detecting and Marking Embedded Radiant Piping for a Basement Perimeter Waterproofing Installation

For more information, please go to the top right corner and click "Navigate."